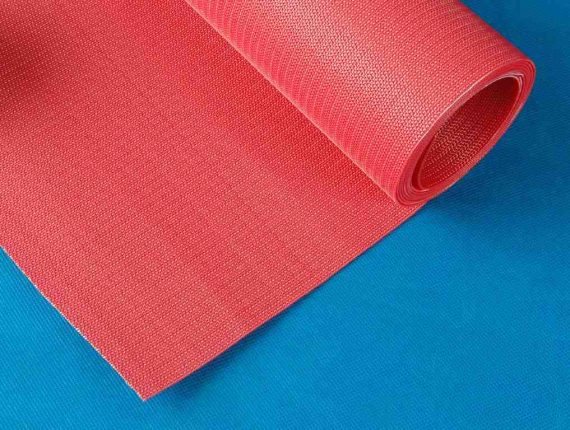

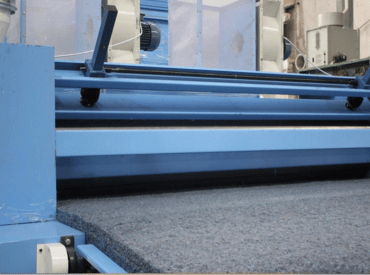

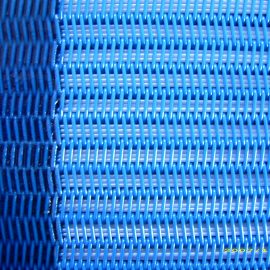

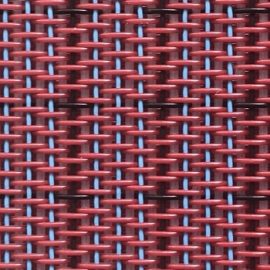

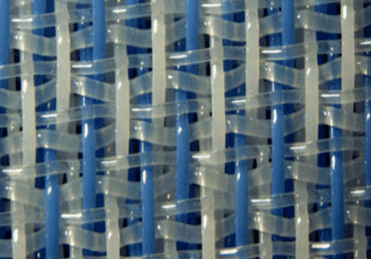

Our Airlaid nonwoven formation belt can be offered for any type of spunlace process, independently from your type of spunlace fabric rolls production (hygiene & cleaning, medical, apparel, furniture, filtration, geotextile, automotive and others). It could be you are producing hydro-entlangled (spunlaced) rolls at low water pressure as for example 35 bar for cotton pads or at 100 bar for wipes or for example at 400 bar for the air or liquid filtration market or for finishing after a mechanical needle machine or after a spunbond (continuous filaments) extruder or to bond SPC, in any case the spunlace lines require high quality airlaid nonwoven formation belt.

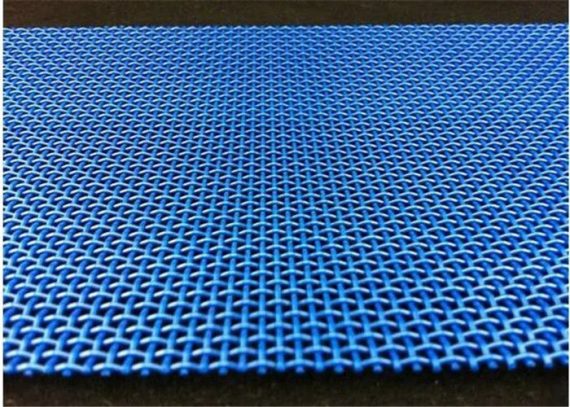

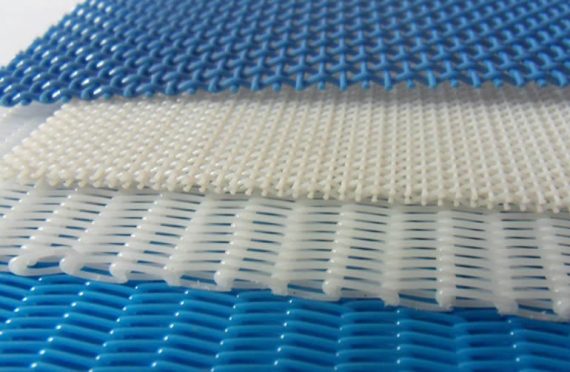

In airlaid dust-free paper applications, Anthonor® designed the formation belt with improved belt quality and anti-pollution properties from wood pulp air flow molding, sizing drying and other aspects, and the design of different areas of the air permeability parameters are different, the mesh edge processing method is also based on the difference in the customer’s production process, and the intensity of processing is more stable, the use of a power grid overcomes the occurrence of product cloud spots, and the web builds more evenly.

| Type | Diameter(mm) | Density yarn(counts/cm) | CFM | Thickness (mm) | Weight (gsm) | ||

| Warp | Weft | Warp | Weft | ||||

| AH-AF01 | 0.50 | 0.50 | 20.5 | 16 | 700 | 1.8 | 1200 |

| AH-AF02 | 0.43×0.70 | 0.70 | 18 | 11 | 900 | 2.1 | 1050 |

| AH-AF03 | 0.52×0.50 | 0.3×0.70 | 16 | 13 | 750 | 1.6 | 1000 |

| AH-AF04 | 0.52×0.50 (antistatic) | 0.45×0.60 | 20 | 15 | 600 | 1.6 | 1010 |

| AH-AF05 | 0.38×0.52 | 0.50×0.60 | 20.5 | 18 | 650 | 1.45 | 1100 |

| AH-AF06 | 0.50 | 0.50 | 8.5 | 9 | 900 | 0.95 | 520 |

| AH-AF07 | 0.68 | 0.70 | 7 | 6.5 | 850 | 1.3 | 620 |