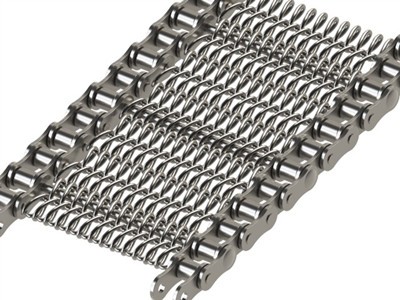

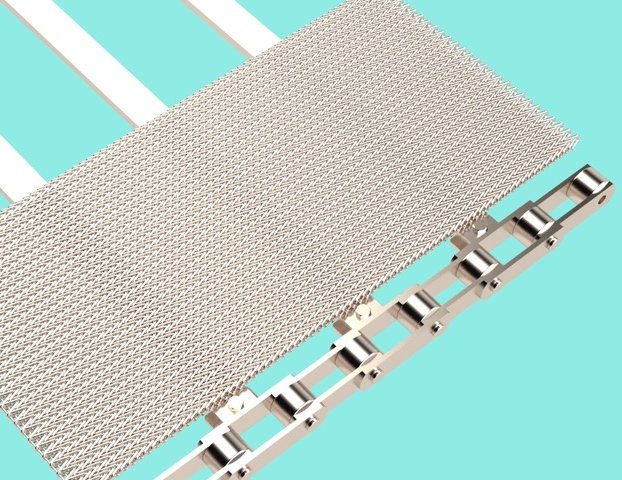

Positive Drive Conveyor Belting

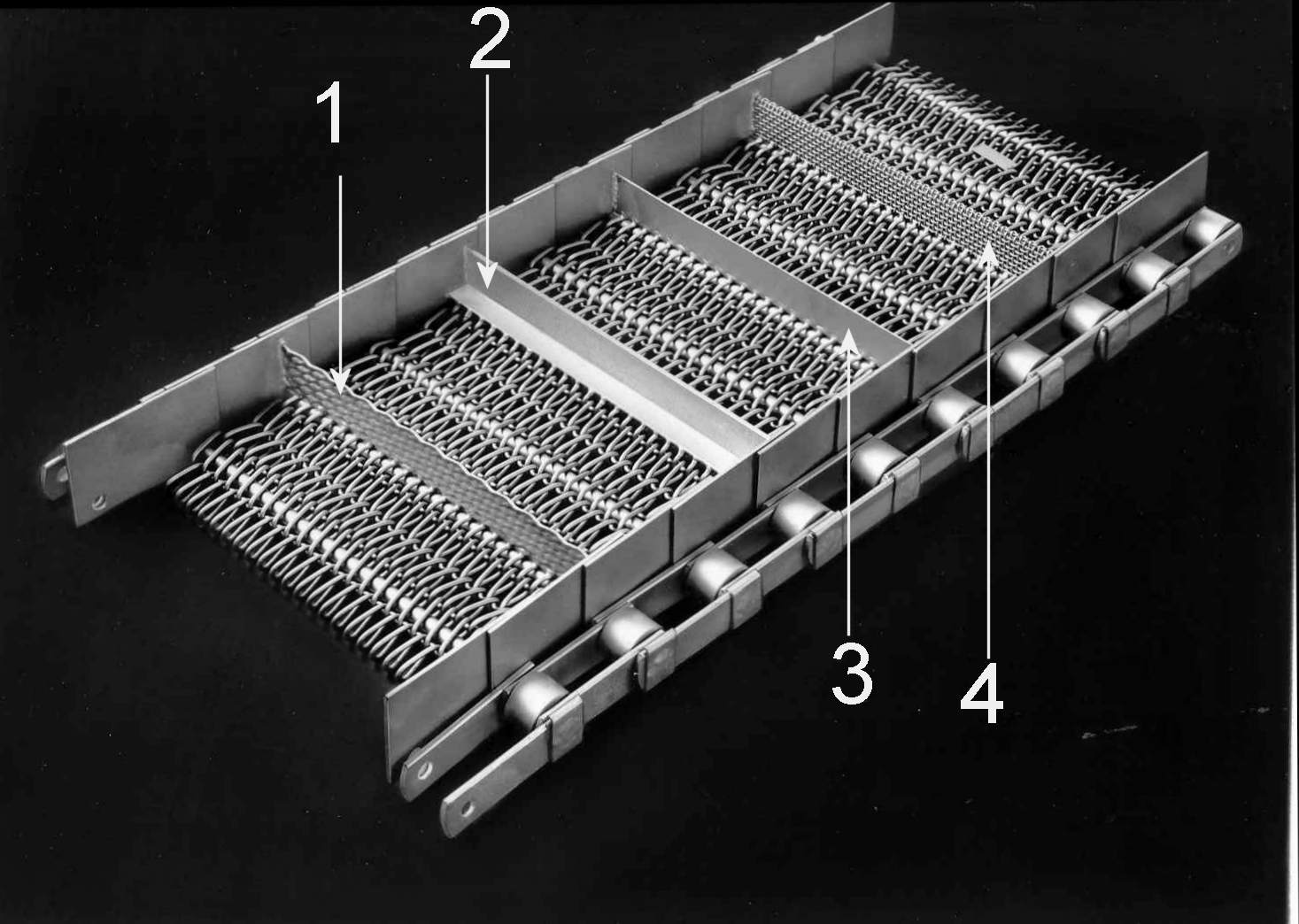

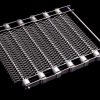

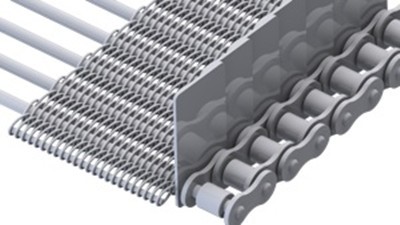

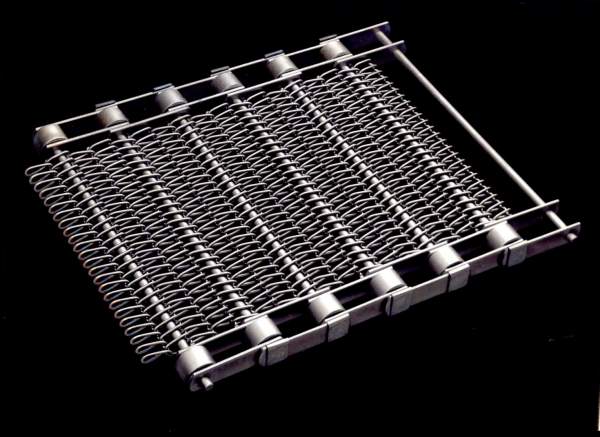

Chain Weave belts assure positive, true forward movement under the most difficult conditions.Rugged and durable Conveyor Belts. Chain Drive Conveyor Belts are used in heat treating, metalworking, food processing, snack food, ceramics and various other applications.They are efficient in any conveying application where the advantages to positive drive contribute to a more effecient operation.Conveyor belt tracking and conveyor belt alignment are simplified with this belt style. The conveying application range is greatly increased by using our Chainweave Conveyor Belt.

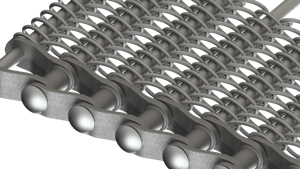

Under moderate temperatures chain drives are very desirable and actually do the driving, the belt itself being used as a conveying medium only.For high temperature work where chain drive is desirable the belt is constructed with a chain of special heat resistant alloy.Practically any link chain or roller chain may be used.

Applications include Foundry Conveyor Belts, Forging Conveyor Belts, Heat Treating Conveyor Belts and more.

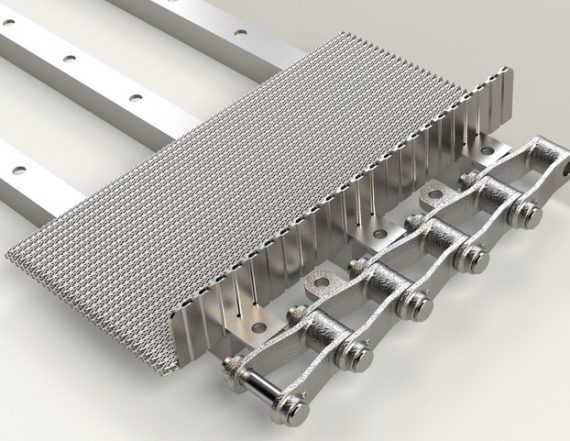

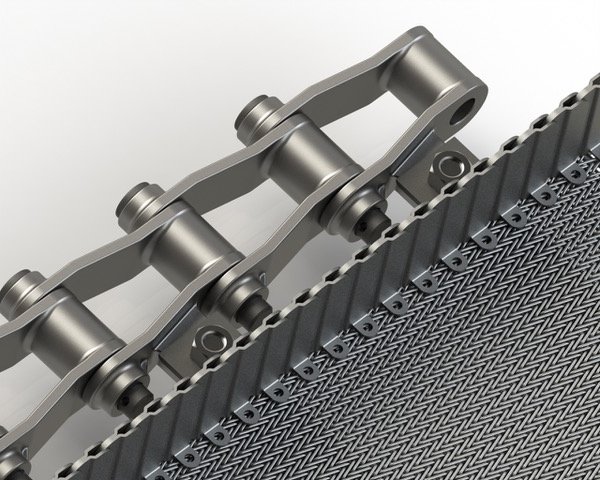

Our Chain Drive belts are constructed by attaching any of the chain listed below, including Roller Chain, Engineering Series Roller Chain and Pintle Chain

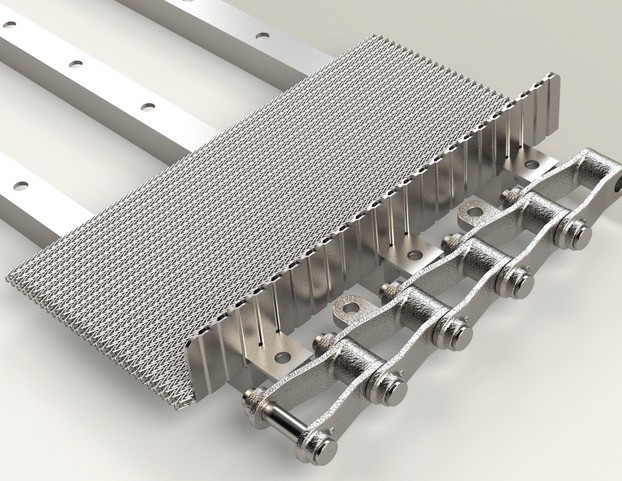

Bars, angles, channels, rods, pipe or tubing are go thru the mesh and into the eye of the chain acting as the chain pin. For tight woven wire mesh Bars and Channels are used and welded or bolted to the mesh and attached to the chain with Chain attachments.

Flex Plate Edges (also known as sideguards or sidewings can be attached to the edges of the conveyor belt. On our tightly woven wire mesh styles, we also offer Flanged Upturned mesh edges

Flights or Dividers can be welded across the width of the Conveyor Belt.

Our Chain Weave Conveyor belts are available in Plain Steel, 304 Stainless Steel, 316 Stainless Steel, and 314 and 330 Stainless Steel.

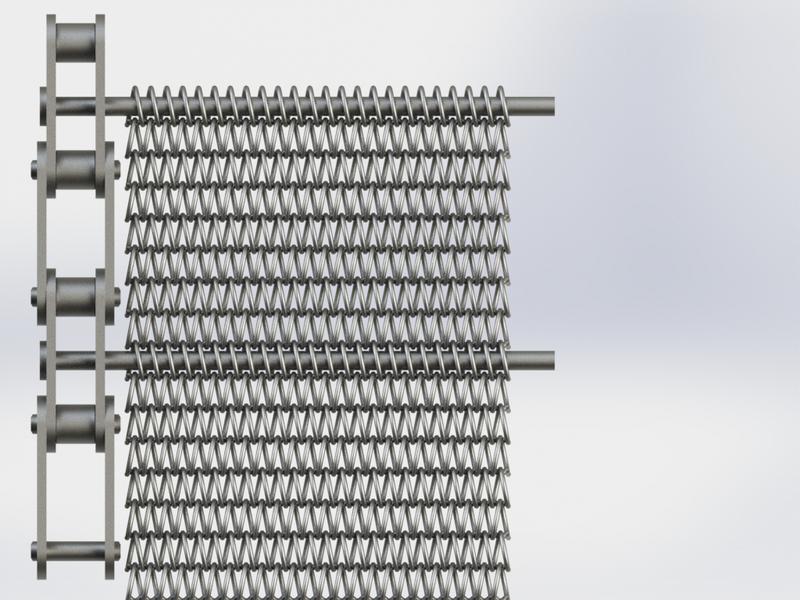

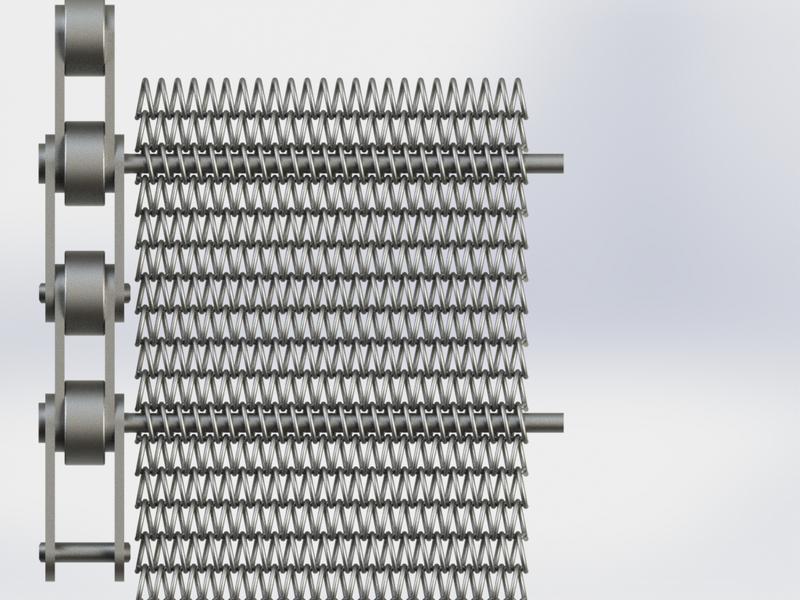

ROLLER CHAIN SERIES CHAINWEAVE CONVEYOR BELTS

Standard or Extended Pitch Roller Chain Conveyor belts are used primarily for handling light and medium loads. Among typical uses for these positive drive conveyor belts are removal of heat treated parts from quench baths, washing and drying applications and the handling of products in the food processing industry. Listed below are the Roller Chains available for our Roller Chain Series of Chainweave conveyor Belts.

AH-R-035, AH-R-040, AH-R-050,AH-R-060, AH-R-080, AH-C240, AH-C242, AH-C250, AH-C252, AH-C260, AH-C262, AH-C280, AH-C-282 is all available.

STANDARD ROLLER CHAIN EXTENDED PITCH ROLLER

Chain Pitch Rod Size Chain Pitch Rod Size

AH-CC313 3″ .438 an Audubon Chainweave Positive Drive Conveyor Belt.Standard construction on

AH-CC413 4″ .438 the engineering roller series uses our Mesh,with a rod inserted through the mesh

AH-CC419 4″ .500 and the eye of the chain. Rod size is based on conveying application,belt support

AH-SS1114 6″ .625 and product load.If a tight cordweave mesh is required,then attachments are put

AH-SS1116 6″ .562 on the chain,and bars/channels will be connected to the chain on the underside of the mesh (rather than a rod and the mesh construction).

Chain Pitch Rod Dia

AH445 1.630″ .312

AH452 1.506″ .375

AH455 1.630″ .438

AH462 1.634″ .438

AH4062 1.634″ .438

AH488 2.609″ .438

AH4102 3.075″ .750

AH4124 4.063″ .812

ROLLER CHAIN: AH-R-040, AH-C240, AH-C242

ROLLER CHAIN: AH-R-050, AH-C250, AH-C252

ROLLER CHAIN: AH-R-060, AH-C260, AH-C262

ROLLER CHAIN: AH-R-080, AH-C280, AH-C282

ENGINEERING ROLLER CHAIN: AH-CC313

ENGINEERING ROLLER CHAIN: AH-CC413

PINTLE CHAIN: AH445

PINTLE CHAIN: AF462

Mesh Upturned Edges and Plate edges available

Flex Plate Edges are available in a height from 1″ to 5″ high.

Available in height of your choice, centered per your specifications. Flight Dividers assist in dividing the product being conveyed. Flight types include rigidized flights, Angle Flights, Flat Flights and wire mesh flights.