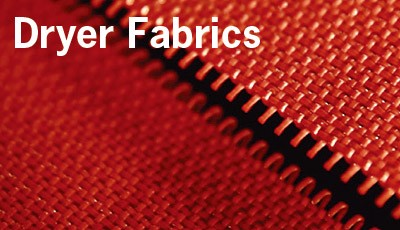

Polyester dryer fabric/Polyester mesh dryer screen/Polyester dryer belt/Paper making dryer fabric/Paper making mesh dryer screen

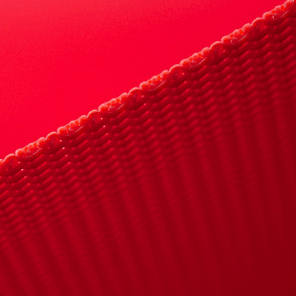

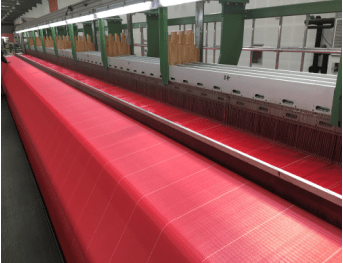

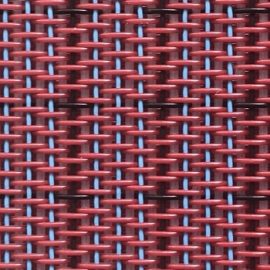

Polyester dryer fabrics is using flat wire, the contact area between silk surface and paper can be increased, so the heat transfer between cylinder and paper is promoted. And flat wire dry fabric body thin, when water vapor through the mesh, reduce water vapor condenses the opportunity, can effectively improve the drying efficiency. Flat wire dry fabric surface is smooth, in the paper drying process flat screen and circular screen compared to the net mark is lighter. Because of the anti-hydrolysis monofilament, the service life of the dry net has been extended effectively and the economic benefit is greatly improved.

Description

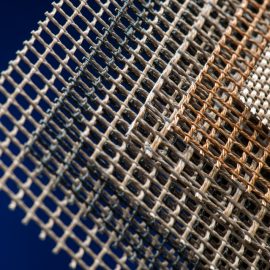

Polyester dryer fabrics are woven from warp threads and weft threads, warp and weft threads are used for hydrolysis-resistant polyester materials, the meridian includes the top and bottom warp, the two meridians are one group, and are woven through two sets of four meridians with two different diameters, the warp threads are flat filaments and the weft is round wire, the section size of the flat wire meridian is 0.32mm x 0.80mm, the diameters of the two different sections of the circular filaments are 0.40mm, 0.60mm or 0.70mm.

Advantage

1.Full monofilament structure, with anti-pollution, anti-hydrolysis

2.Keep clean and dry

3.Good heat transfer, no traces

4.Stable and better wear resistance

5.Long life, easy to clean

6.100% high strength anti-hydrolysis monofilament

7.66% of PPS monofilaments 18-25 cm

8.PEEK spiral ring interface: No net marks, high strength, easy to install

Application

1.Newsprint.

2.Corrugated paper.

3.Cultural paper.

4.Tissue paper.

5.Packing paper.

6.Toilet paper.

7.Kraft paper.

8.Testliner.

9.Paperboard.