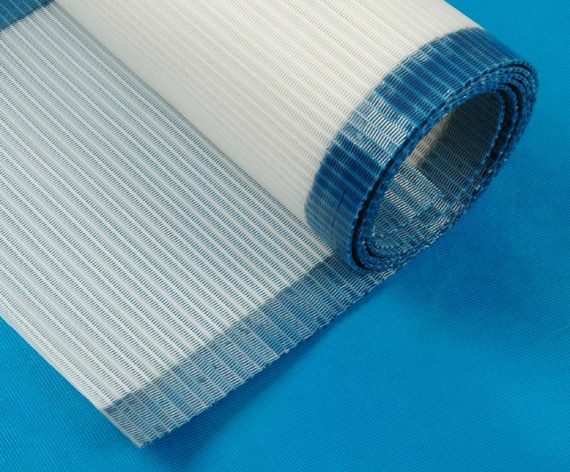

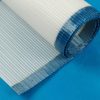

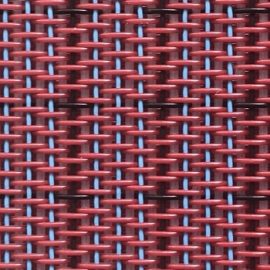

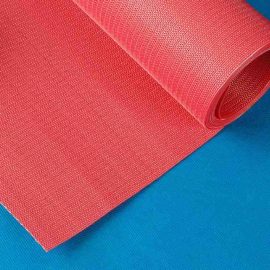

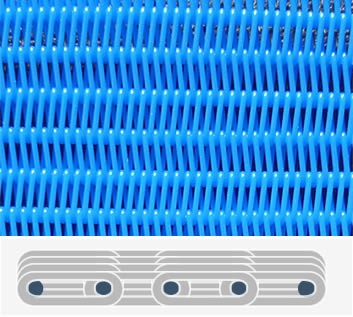

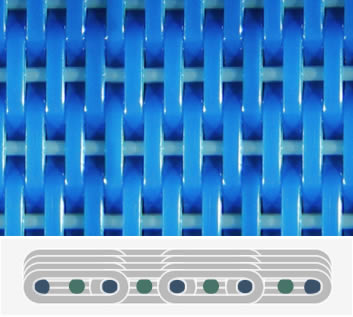

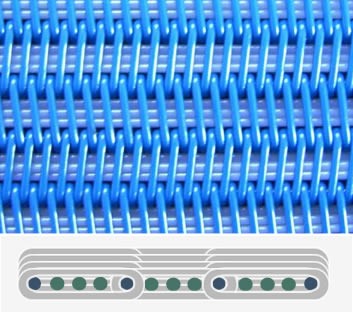

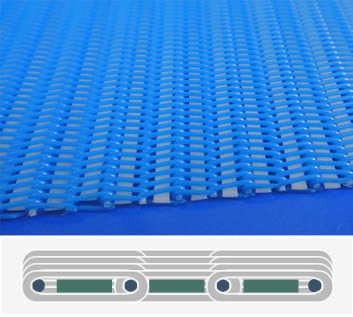

Polyester spiral dryer belt/Spiral mesh belt/Spiral dryer fabric/Spiral dryer mesh screen

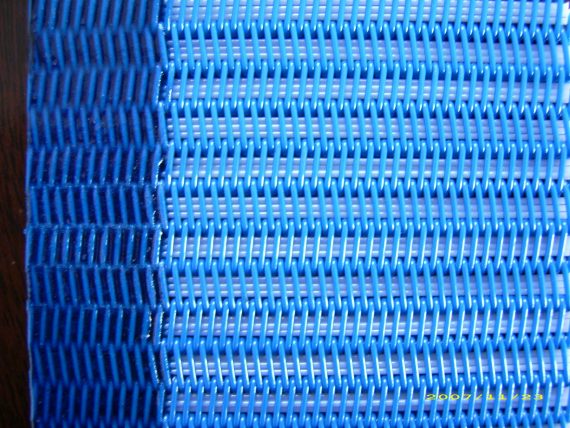

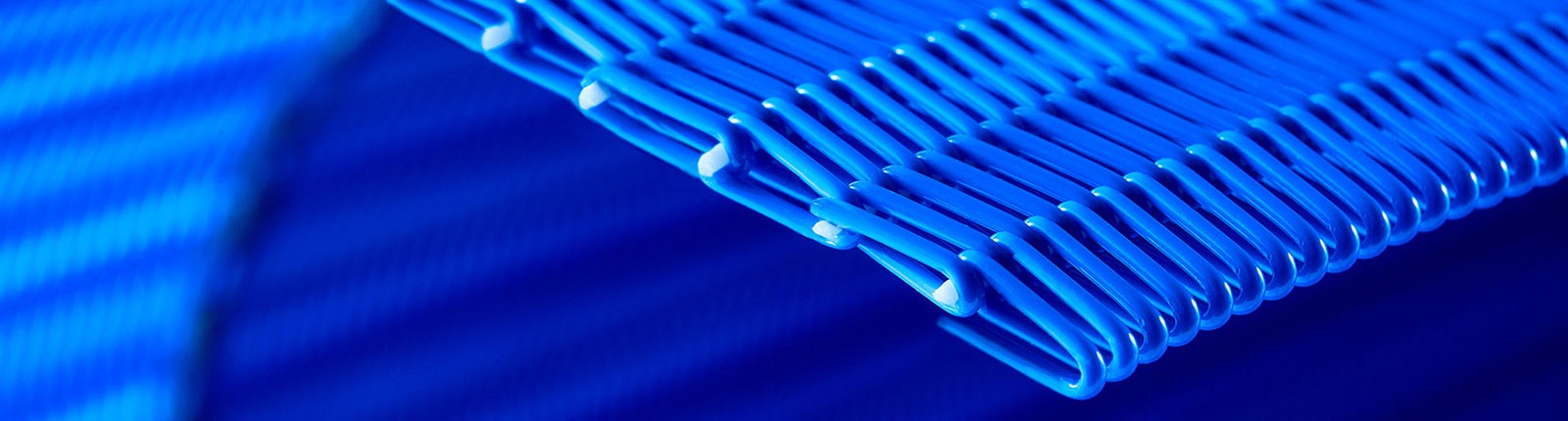

Spiral dryer belt have specially designed spiral structure allows for rapid drainage, superb distortion resistance and eliminates the needs for conventional seams compared with the woven polyester dryer fabric. Meanwhile, it allows the filtered cakes to be removed quickly. According to your requirements, spiral polyester dryer fabric can be fabricated with round yarns or flat yarns.

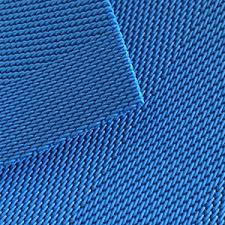

Normally, the round one is ideal for paper drying, screen printing and dyeing. With a long service life, it is easy to be joined together and suitable for coaling washing machine and various horizontal filters. In contrast, the flat yarn spiral dryer is recommended to be used in high speed paper drying machines owing to its smoother surface, better wear resistance, later contacting area, most of all, improved paper drying performance.

Advantage

1.Effective control of fluff

2.Uniform size

3.Smooth surface

4.Easy to operate

5.Adjustable air permeability

6.Monofilament water resistance system

Application

1.Paperboard.

2.Newsprint,writing paper.

3.printing paper,kraft paper.

4.Carbonless paper,copper print.

| Loop size | Type | Thread Diameter (mm) | Thickness (mm) | Weight (gsm) | Air Permeability (m3/m2.h@200pa) | |

|---|---|---|---|---|---|---|

| Warp | Weft | |||||

| Large loop | AH-SD-1 | 0.9 | 1.1 | 3 | 1700 | 20500 ± 1500 |

| AH-SD-2 | 0.9 | 1.1 | 3 | 1900 | 5250 ± 500 | |

| Medium loop | AH-SD-3 | 0.7 | 0.9 | 2.5 | 1400 | 18500 ± 1500 |

| AH-SD-4 | 0.7 | 0.9 | 2.5 | 1700 | 4750 ± 500 | |

| Small loop | AH-SD-5 | 0.5 | 0.7 | 1.9 | 1100 | 15000 ± 1500 |

| AH-SD-6 | 0.5 | 0.7 | 1.9 | 1400 | 4000 ± 500 | |