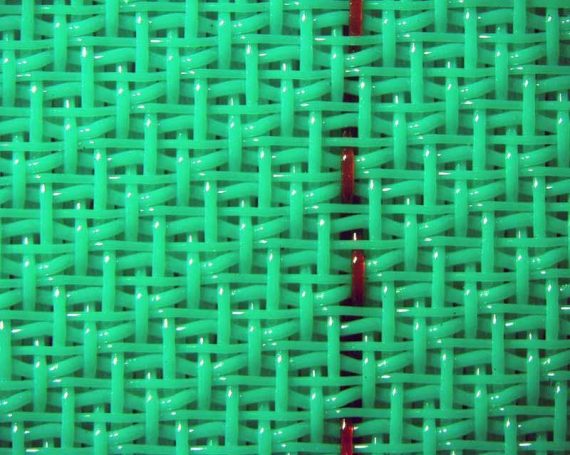

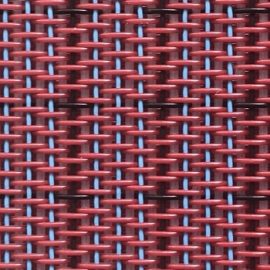

Single layer polyester forming fabric/Single layer synthetic forming wire/Single layer synthetic forming mesh /Single layer paper forming wire

Single layer forming fabrics is also called paper making forming belts, widely used for paper making machine forming section and transportation, simple structure and newest design could ensure good air permeability and drainage performance.

Description

The single layer polyester forming fabrics is the simplest forming net, It includes four different forms:

1. 2-shed (one up and one down) : The design is mainly used in sewage treatment plants, sludge dewatering machines, etc.

2. 3-shed (one up two down): Mainly used for sludge dewatering machine, washing machine and bleaching machine.

3. 4-shed (one up and three down) : Mainly used for various paper machines.

4. 5-shed (one up and four down) : Mainly used to produce all kinds of kraft paper, tissue paper, writing paper, printing paper, etc.

Advantage

1.Simple structure of single layer forming network, good dewatering and good air permeability.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Applications

1. Pulping, pulp washers.

2. Sludge dewatering, black liquor extraction.

3. Writing papers, printing papers, kraft papers, newsprint papers, corrugated paper, straw boards,tissue papers and so on.

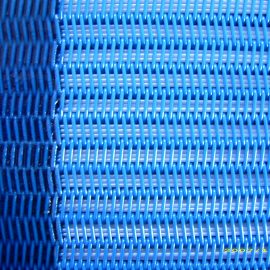

1.5 layer polyester forming fabric/1.5 layer synthetic forming wire/1.5 layer synthetic forming mesh /1.5 layer paper forming wire

1.5 Layer forming fabrics is woven in warp and weft weaving method, the material is polyester monofilament, so it also called polyester forming fabrics,1.5 layer polyester forming wire is similar to double layer polyester forming mesh structure, mainly used in the production of wrapping paper, printing paper, writing paper, toilet paper, tissue paper, corrugated paper.

Description

The 10-shed 1.5 layer forming fabric has stronger dewatering performance and secondary Fiber Recycling and Straw Pulping Application for papermaking long paper machine or long wire paper machine with a weight of between 50-220g to reduce paper machine wear.

Advantage

1.Stronger dewatering performance, long life.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Application

1.Newsprint.

2.Writing paper.

3.Printing paper.

4.Kraft paper.

5.Corrugated paper.

6.Tissue paper.

7.Cultural paper

8.Warpping paper

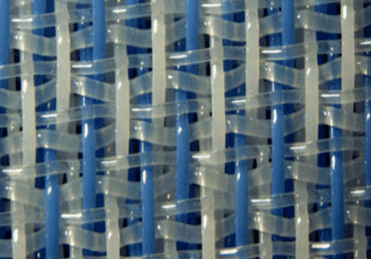

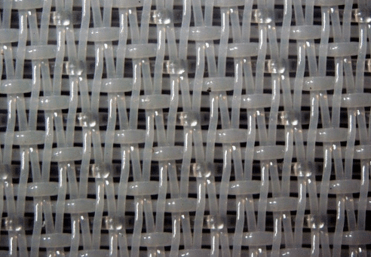

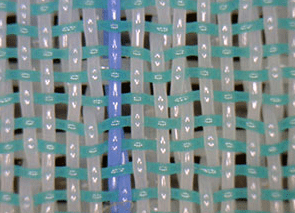

Double layer polyester forming fabric/Double layer synthetic forming wire/Double layer synthetic forming mesh /Double layer paper forming wire

Double layer forming fabrics is common polyester forming conveyor belt for paper making manufacturer, highly unique design structure can avoid Longitudinal load and Horizontal wrinkling, double layer forming wire will increase the mesh stable and drainage,improve mesh fabrics work life.

Description

With the increase in the speed of the paper machine and the increase in the width of the polyester forming fabric, the double layer forming fabric is indeed an overhead.

The 8-shed double-layer forming wire includes a group of longitudinal fiber healds and two sets of transverse fiber heals, which allows the small fibers to stay on the top layer, and the use of thicker fiber weaving at the bottom helps to obtain better sheet forming characteristics, this double-layer design will gain more stability in size than a single-layered mesh design.

The 16-shed double-layer forming mesh creates a new concept that can increase the life of the net cloth without affecting the quality of the paper, after the life of the bottom material of the net is increased, the life of the entire net cloth is usually improved, usually 16-shed forming fabrics are used for the production of paper machines and coarse kraft paper machines, double mesh screens can be from 60/cm to 32/cm.

Advantage

1.High dimensional stability, unique weaving structure can resist longitudinal load and horizontal wrinkling.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Application :

1.Paperboard.

2.Newsprint,writing paper.

3.Tissue paper.

4.printing paper,kraft paper

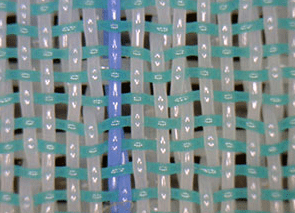

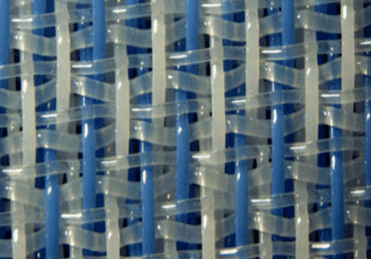

2.5 layer polyester forming fabric/2.5 layer synthetic forming wire/2.5 layer synthetic forming mesh /2.5 layer paper forming wire

The design of the 2.5 layer forming fabrics fully accounts for the higher degree of fiber retention without losing its dewatering properties, this design has a higher fiber support index than a double-layer wire design, which is achieved by adding additional transverse braiding lines on top of the double-layer polyester mesh, this greatly reduces the distance between the top line and the line and provides better support for fine fibers.

Description

The 8-shed 2.5 layer forming fabric is the most common 2.5 layer polyester forming mesh. its weaving effect greatly increases the fiber support index due to the addition of a fine weave at the top. The ratio of the top and bottom wefts is 2:1.

The 8-shed above and 16-shed below weaving technology, its performance greatly improves the surface smoothness and higher paper support effect.

Advantage

1.Good top layer smoothness;

2.Excellent formation and excellent fiber support;

3.No fabric marking and easy to clean;

4.Very good stable and wear resistance;

5.Good paper threading and retention.

Application :

1.Paperboard.

2.Newsprint,writing paper.

3.Tissue paper.

4.printing paper,kraft paper.

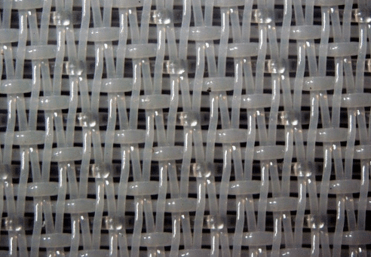

Triple layer polyester forming fabric/Triple layer synthetic forming wire/Triple layer synthetic forming mesh /Triple layer paper forming wire

The triple layer forming fabrics main used in the forming part of paper machine, Our three-layer polyester forming mesh could let us better distinguish the weaving design between the machine side and the paper side of the fabric, and the upper are the same mesh number with lower layer,which results in excellent paper sheet surface and stable high life potential.

Description

An important advantage of our three layer forming fabrics is low warp density,another anvantage of this types: the weft wire of the wear surface spans a lot, that could gives the polyester forming fabrics a long life postential,the weft span would be 8 warp rather than common 6 or 5 warp, choosing the best polyester forming mesh type will save many costs in terms of clean operation, additive use, and vacuum, water, and electricity consumption.

Advantage

1.For paper and board grades that require excellent printability.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Application

1.Cigarette tissue,cigarette finer tissue,copy tissue,LC,LWC.

2.Newsprint,writing paper,carbonless paper,copper print.

3.Tissue napkin,tolite tissue.

4.Top or liner side for kraft and card board.