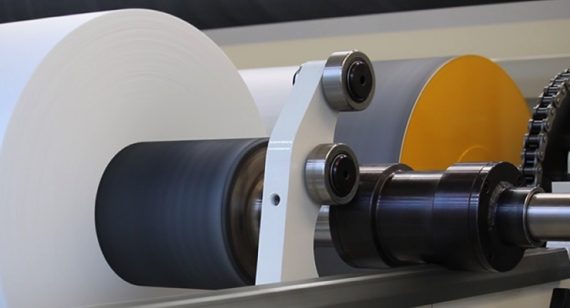

Our spunlace nonwoven formation belt can be offered for any type of spunlace process, independently from your type of spunlace fabric rolls production (hygiene & cleaning, medical, apparel, furniture, filtration, geotextile, automotive and others). It could be you are producing hydro-entlangled (spunlaced) rolls at low water pressure as for example 35 bar for cotton pads or at 100 bar for wipes or for example at 400 bar for the air or liquid filtration market or for finishing after a mechanical needle machine or after a spunbond (continuous filaments) extruder or to bond SPC, in any case the spunlace lines require high quality spunlace nonwoven formation belt.

Applications and production processes

Hydroentanglement/Spunlace:Compacting belts, pre-wetting belts, bonding belts, dewatering belts, endless seam on very fine covers for bonding cylinders, patterning and aperturing specific marking fabrics,spunlace forming belt for TAD dryers.

Thermal compacting and bonding:spunlace nonwoven formation belt for TAD dryers,twisted cloth belts made of metal for flat-bed dryers.

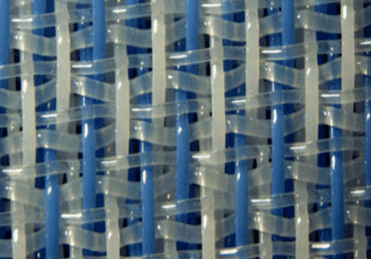

Our spunlace nonwoven formation belt type AH-SFS24M is mainly used for punching of spunlace nonwoven cloth,it will install in spunlace machine’s cylinder with nonmarking endless seam.

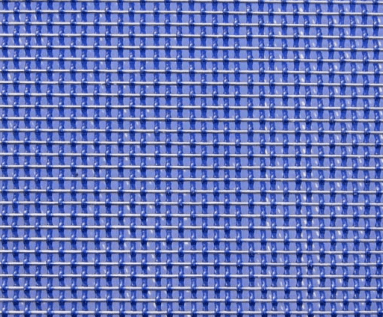

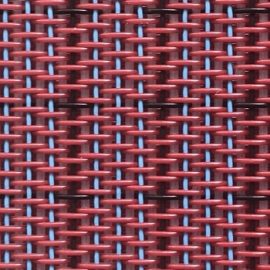

Our spunlace nonwoven formation belt type AH-SF76M and AH-SF100M are widely used for entangling and forming of spunlace nonwoven cloth with smooth surface and strong quality.

| Product | Wire diameter (mm) | Wire density (counts/inch) | Gram weight (gsm) | Thickness (mm) | Air permeability (L/m2.S@200pa) | ||

| Warp | Weft | Warp | Weft | ||||

| AH-SF76M | 0.22(PET) | 0.25(PET) | 70-75 | 50-55 | 350 | 0.55 | 3000-3300 |

| AH-SF100M | 0.15(PET) | 0.20(PET) | 100-103 | 75-77 | 320 | 0.35 | 2000-2200 |

| AH-SFS24M | 0.50(PET) | 0.40 (316L SS) | 22-24 | 25-27 | 1300 | 1.2 | 6500-6700 |

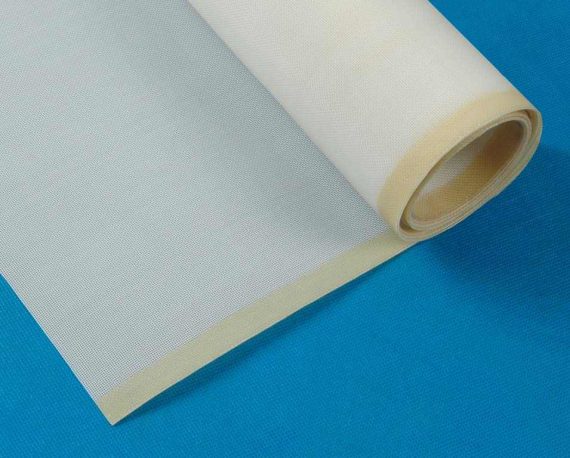

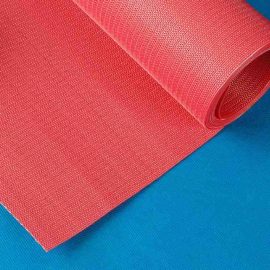

Seam type and edge coating

Nonmarking endless seam Yellow color edge coating Blue color edge coating